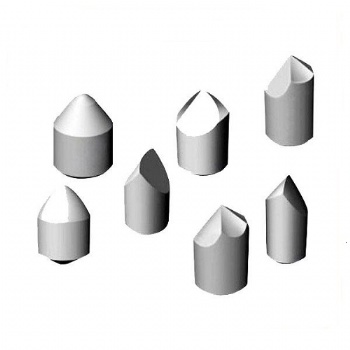

We offers to the client exceptional quality tungsten carbide mining inserts (mining button bits). Cemented carbide mining inserts (tungsten carbide buttons for mining) provided by RuiYi Carbide Industry are made available in various sizes. Supreme quality and durability characterize the range of carbide buttons bits for mining purpose delivered by us in the market.

Product description

Tungsten carbide wear parts and non-standard parts,precision wear parts.

Cemented carbide has excellent performance and is widely used in industry.

Good wear resistance and high hardness, make it suitable for high temperature, abrasion, corrosion wear parts, mechanical parts and drawing die etc.

In recent years, carbide has become the best alternative to steel in many industrial application

Features of tungsten carbide wear parts

1. Used for 100% tungsten carbide raw material.

2. With high abrasion resistance and resistance.

3. With long life time.

4. With High bending strength.

5. With stable chemical properties, acid and alkali resistance, and does not even oxidize at high temperature.

6. Products with advanced equipment and perfect workmanship.

7. All products go through in-process and final inspection.

8. Stable and continuous production ability.

9. All products must be inspected strictly.

10. Our fine manufacturing management and professionals make sure we can provide you with more competitive high cost-performance products

Different grades of carbide, the application of carbide blank and its wear-resisting parts

Grade | Wc | Co | Density g/cm³ | Hardness HRA |

YG6 | 94 | 6 | 14.7-15.1 | 89.5 |

YG8 | 92 | 8 | 14.6-14.9 | 89 |

YG11 | 89 | 11 | 14.3-14.8 | 88 |

YG15 | 85 | 15 | 13.9-14.2 | 86.5 |

YG20 | 80 | 20 | 13.4-13.8 | 83.5 |

YG20C | 80 | 20 | 13.4-13.8 | 82 |

YL10.2 | 90 | 10 | 14.40-14.55 | 92.5 |

YGH20 | 90 | 10 | 14.2-14.5 | 86.0 |

YGH25 | 88 | 12 | 14.0-14.3 | 84 |

YGH30 | 85 | 15 | 13.8-14.2 | 83.5 |

YGH40 | 82 | 18 | 13.4-13.9 | 83 |

YGH45 | 80 | 20 | 13.3-13.9 | 82 |

YGH55 | 74 | 26 | 12.6-13.2 | 81 |

YGR20 | 90 | 10 | 14.2-14.8 | 85 |

YGR25 | 87.5 | 12.5 | 14.0-14.3 | 83 |

YGR30 | 85 | 15 | 13.8-14.3 | 83 |

YGR40 | 82 | 18 | 13.5-13.9 | 82 |

YGR45 | 80 | 20 | 13.4-13.9 | 80.5 |

YGR55 | 75 | 25 | 12.9-13.4 | 79 |

YGR60 | 70 | 30 | 12.6-13.1 | 78.5 |