A snow plow carbide cutting edge is a type of blade used on the bottom of a snow plow to scrape and remove snow and ice from surfaces.

It is made of a durable material called carbide, which is known for its hardness and resistance to wear and tear. The carbide cutting edge is designed to provide a longer lifespan than traditional steel cutting edges and can be more effective in removing tough, compacted snow and ice.

It is also less likely to damage the surface being cleared, such as pavement or concrete.

Snow shovel carbide cutting edges are suitable for shoveling snow in various environments and conditions, including snow with different hardness and density, low temperature environments, etc.

Snowplow carbide cutting edges are a key component in snowplows for efficient snow removal. Carbide, due to its unique material properties, is widely used in the manufacture of such cutting edges

Cemented carbide is an alloy material made from hard compounds of refractory metals (such as tungsten carbide WC, titanium carbide Tic, etc.) and bonding metals (such as cobalt Co) through a powder metallurgy process. It has properties such as high hardness, high strength, high wear resistance and high elastic modulus.

The hardness of cemented carbide is very high, and its hardness range is usually between 86 and 93HRA, which is equivalent to 69 and 81HRC, second only to diamond. This high hardness allows the carbide cutting edge to remain sharp for a longer period of time and reduce wear during snow shoveling.

Carbide can still maintain its basic properties at a temperature of 500°C, and still has a high hardness even at 1000°C, which allows the snowplow carbide cutting edge to maintain good working performance in high temperature environments.

Due to the high hardness and wear resistance of carbide, the snow shovel carbide cutting edge can quickly and effectively remove snow and improve snow shoveling efficiency.

Carbide insert blades for snow plow applications are available in four profiles: 3/4 x 5, 3/4 x6, 7/8 x5 and 7/8 x6

Carbide insert blades are plow blades with slugs of tungsten carbide brazed into the thickness of the steel blade.

carbide is an extremely durable substance that substantially extends blade life up to 20times over standard carbon steel blades

How to reduce the wear of the carbide cutting edge of the snowplow?

To reduce the wear of the carbide cutting edge of the snowplow, the following aspects can be considered:

1. Optimize cutting parameters

Cutting speed: Adjust the cutting speed reasonably to avoid excessive heat generated by the cutting edge and snow due to excessive cutting speed, thereby reducing the hardness and toughness of the cutting edge.

Feed speed: Properly control the feed speed to avoid increased wear caused by overload use or excessive cutting speed.

Cutting depth: Set the cutting depth reasonably to ensure that the cutting edge is evenly stressed during the cutting process and reduce wear caused by excessive cutting depth.

2. Change the structure of cemented carbide

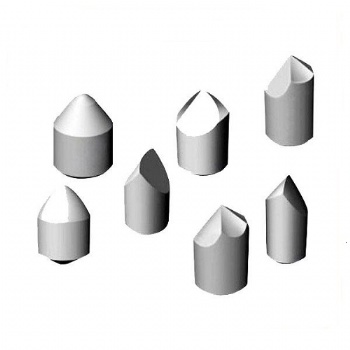

Adopt special structure: Use cemented carbide with special shape, special composition and nanocrystal structure to reduce the wear of the cutting edge. This design improves the performance of the cutting edge and extends its service life.

3. Use tool coating

Coating material: Carbide cutting edge is surface modified and coated with titanium alloy, molybdenum alloy or other compound coatings. These coatings can effectively prevent direct contact between the cutting edge and snow, reducing wear.

Coating technology: Use multi-layer coating technology to improve the adhesion and wear resistance of the coating. This helps increase the hardness and toughness of the cutting edge and reduces wear.

4. Maintenance

Avoid collision: During processing, avoid direct collision between the cutting edge and hard or sharp objects to avoid scratches or chipping.

Storage environment: Carbide cutting edges should be stored in a dry and ventilated environment to avoid corrosion or oxidation caused by moisture or high temperature.

Regular cleaning and lubrication: Use a soft cloth or special cleaning agent to clean the cutting edge surface regularly to ensure it remains clean. For parts that require lubrication, use special lubricants to reduce friction and wear.

5. Regular maintenance and replacement

Regular inspection: During use, regularly check the wear of the cutting edge, including whether the edge is sharp, whether there is chipping, whether there are cracks, etc.

Timely replacement: Once the cutting edge is found to be severely worn or defective, it should be replaced in time. Avoid the decline in processing quality or safety accidents caused by continued use of worn cutting edges.

6. Proper use and training

Understand usage skills: Understanding and mastering the basic knowledge and usage skills of cemented carbide cutting edges will help to better select appropriate cutting parameters and processing methods.

Participate in training: Learn how to adjust cutting parameters, optimize processing techniques, etc., to improve the efficiency and life of the cutting edge by participating in training or reading relevant books and materials.

Farm plow blade | joma plow blades | Joma snow plow blades | highway snow plow cutting edge | snow plow blade carbide inserts | municipal snow plow blades | carbide snow plow shoes | carbide tipped grader blades | snowplow blades | snow plow blades | Joma plow blades | carbide plow blade Joma shoes | Carbide plow blade Joma shoes for sale | cutting edges for plows | carbide snow plow shoes | best snow plow cutting edge | snowplow blades | serrated snow plow cutting edge | heavy duty plow cutting edge | snow plow cutting edge | Joma style snowplow blade | alternative for Joma Snow plow blades | Direct replacement of Joma plow blade | rubber carbide plow blades | carbide insert snow plow blades | steel snow plow blades | Tungsten carbide cutting edges | carbide snow plow blade inserts | carbide plow blades | snow plow wear blades | pave snow plow blades for sale | snow plow replacement blades | china snow plow blade manufacturers