A carbide oscillating snow plow blade is a specialized component designed for snow removal equipment, combining the durability of carbide with an oscillating mechanism to enhance performance in harsh winter conditions. Here’s a detailed breakdown:

Carbide Construction:

Material: Tungsten carbide edges or carbide-tipped segments are bonded to the blade’s cutting edge. Carbide is exceptionally hard and wear-resistant, making it ideal for cutting through ice, compacted snow, and abrasive road debris (e.g., salt, gravel).

Durability: Outlasts traditional steel blades, especially in high-abrasion environments.

Oscillation Mechanism:

Movement: The blade oscillates (rocks or pivots slightly) during plowing to maintain consistent contact with uneven surfaces (e.g., gravel driveways, cracked pavement). This motion reduces wear on the blade and prevents "digging in" or blade damage.

Adjustability: Some systems allow manual or automatic oscillation adjustments to adapt to terrain.

Applications

Residential/Commercial Plowing: Ideal for driveways, parking lots, and roads with mixed surfaces (e.g., asphalt, gravel).

Ice Breaking: Carbide edges chip away at thick ice layers more effectively than steel.

Abrasive Environments: Suited for areas treated with road salt or sand, which accelerate wear on standard blades.

Advantages

Extended Lifespan: Carbide resists chipping and wear, reducing replacement frequency.

Improved Efficiency: Oscillation ensures even blade contact, reducing operator effort and fuel consumption.

Versatility: Works on both hard surfaces (concrete) and loose substrates (gravel) without gouging.

Reduced Maintenance: Less prone to rust and deformation compared to steel blades.

Comparison to Traditional Blades

| Feature | Carbide Oscillating Blade | Standard Steel Blade |

|---|---|---|

| Durability | Excellent (resists abrasion/ice) | Moderate (wears faster) |

| Cost | High upfront cost, lower long-term | Lower upfront cost, higher upkeep |

| Performance | Superior on ice/gravel | Adequate for light snow |

| Maintenance | Minimal | Frequent edge sharpening/replacement |

Who Should Use It?

Municipalities: For plowing salted roads and mixed surfaces.

Contractors: Handling large commercial lots or gravel driveways.

Homeowners: In regions with heavy ice or abrasive winter conditions.

Popular Brands

BOSS Plow: Offers carbide-edged blades with oscillation features.

Fisher Engineering: Known for durable carbide plow systems.

Meyer Products: Provides retrofit carbide blades for existing plows.

Why Choose Carbide Blades for Gravel Driveways?

Carbide oscillating blades are ideal for gravel driveways because they:

✅ Withstand abrasive wear

✅ Protect gravel surfaces

✅ Reduce long-term costs

✅ Enhance safety and efficiency

Whether you’re a contractor, homeowner, or municipal worker, investing in a carbide blade ensures reliable performance and preserves both your equipment and driveway.

Ready to upgrade? Explore our carbide oscillating blades designed for gravel, ice, and heavy-duty plowing!

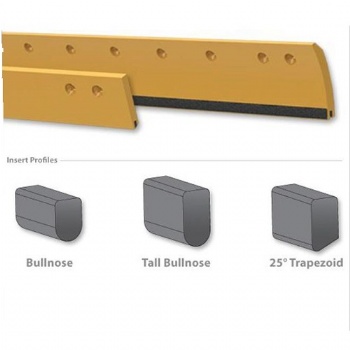

Carbide inserts | Carbide bits | Carbide tips are brazed into a specially prepared groove at the bottom of snowplow blade to substantially extend the wear life of the blades by as much as 20 times over steel alone, giving unmatched wear resistant properties, and making the blade ideal for high speed highway or airport runway plowing. Our inserts come in a wide variety of sizes and styles. Carbide tips are available with either a 25 degree and 40 degree plowing angle or flat plowing surface to assist in various applications. Special tungsten carbide snow plow parts, accessories are available upon request.

Key characteristics:

• Optimum fracture resistance and breakage resistance

• High hardness

• Good wear and shock resistance

• High transverse rupture strength

• Easy to weld

Our Carbide Blades use Virgin or Recycled Tungsten carbide inserts that are placed into milled grooves along the bottom wear surface of the edge giving it unmatched wear resistant properties and making this blade ideal for high speed highway or airport runway plowing.

We also can make Carbide Blades to your specifications

Plowing closer to the real shape of the road clears more snow

The wearing edge has custom tungsten carbide inserts brazed into the bottom surface

Carbide insert snow plow blades feature inserts of tungsten carbide. The wear and abrasion resistant carbide inserts wear longer than any other type of blade in applications requiring long runs and high speeds, such as plowing interstate highways and airports

Carbide Inserts Price | China carbide Inserts Manufacturing | Carbide Inserts Suppliers | Cemented carbide manufacturing process | Carbide cutting tools | Carbide steel Blade | Tungsten carbide Inserts | Tungsten carbide inserts manufacturers | Round Tungsten carbide inserts | Cemented Tungsten carbide inserts | Types of Tungsten carbide inserts | Tungsten Carbide button bits suppliers | Tungsten carbide button inserts | Tungsten carbide button bits | Tungsten carbide buttons | Tungsten carbide buttons supplier China | Tungsten carbide Mining buttons | Tungsten carbide Drill Buttons Tungsten carbide drill bits for concrete | Diamond Core drill bits for concrete | Diamond Core Drill Bits | Dry core Drill bits | Colbalt Drill Bits | Tungsten carbide Drill bit inserts | Colbalt Snow plow blade | Tungsten snowplow blade supplier in China | Tungsten snowplow blade manufacturer | Tungsten carbide Brazed plow blades | Carbide snow plow cutting edges | Joma snow plow blade replacement | Segmented plow blades | Carbide tipped Grader Blades | Snow plow wear blades | Carbide blade wear parts | Tungsten carbide snow plow blades | Highway snow plow cutting edge | Snowplow removal parts | Carbide Inserts brazed Metal Segments Rubber blade | Diamond Core Drill bits for Granite | concrete diamond core Drill bits | Diamond tipped core drill bits | Diamond wet core drill bits | Diamond Coated Core Drill Bits | Core Drill Bits for Granites

A snow plow blade is often mounted onto a vehicle to remove snow and ice from outdoor roads, parking lots, and surfaces. There are also many types of machines or vehicles that can support a snow plow, the most common are: Trucks. Pick-up Trucks. ... Other Heavy Machine Equipment

Joma is a brand, Joma blade which is revolutionary style of snow plow blades consists of carbide inserts encased in rubber. The rubber shell around. The metal significantly increases the product lifespan compared to exposed steel or carbide blades. Snow plow operators experience cost savings through fewer replacements, less equipment downtime, and reduced maintenance time.

We company only sell direct replacements for Joma style snow plow blades,and our blade is alternatives for Joma snow blades that feature a snow plow blade encased in rubber with tungsten carbide inserts that are brazed into metal segments or steel slug.

Farm plow blade | joma plow blades | Joma snow plow blades | highway snow plow cutting edge | snow plow blade carbide inserts | municipal snow plow blades | carbide snow plow shoes | carbide tipped grader blades | snowplow blades | snow plow blades | Joma plow blades | carbide plow blade Joma shoes | Carbide plow blade Joma shoes for sale | cutting edges for plows | carbide snow plow shoes | best snow plow cutting edge | snowplow blades | serrated snow plow cutting edge | heavy duty plow cutting edge | snow plow cutting edge | Joma style snowplow blade | alternative for Joma Snow plow blades | Direct replacement of Joma plow blade | rubber carbide plow blades | carbide insert snow plow blades | steel snow plow blades | Tungsten carbide cutting edges | carbide snow plow blade inserts | carbide plow blades | snow plow wear blades | pave snow plow blades for sale | snow plow replacement blades | china snow plow blade manufacturers